astm b117 salt spray chamber|astm b117 rating scale : member club Q&As on Operation of Salt Fog Test Chambers: The Salt Spray Woes, pH, S.G., Volume of Condensate too low, Concentration too low, etc. . ASTM B117 Salt Fog Test Chamber Operational Q&As, Problems: Salt Spray Woes. Q. With what solution can I unclog the nozzle if it has grains of salt stuck?

WEB10 de set. de 2018 · Descrição do Arquivo. PCSX2 1.6.0 + Bios é um emulador de PlayStation 2: com ele, é possível executar os games lançados originalmente para o console diretamente no seu computador! Um emulador é um software que simula o hardware de outro aparelho. Ou seja, para os jogos de PlayStation 2, o computador é .

{plog:ftitle_list}

WEB7 de jan. de 2024 · Confira resultado do Maracap de hoje e os ganhadores do sorteio deste domingo. Hoje, 07 de janeiro de 2024 (domingo), serão divulgados os resultados e os ganhadores do sorteio pelo Maracap. As informações são oficiais. RESULTADO MARACAP DE HOJE RESULTADO AO VIVOOs ganhadoes serão divulgados após .

astm b117 standard pdf

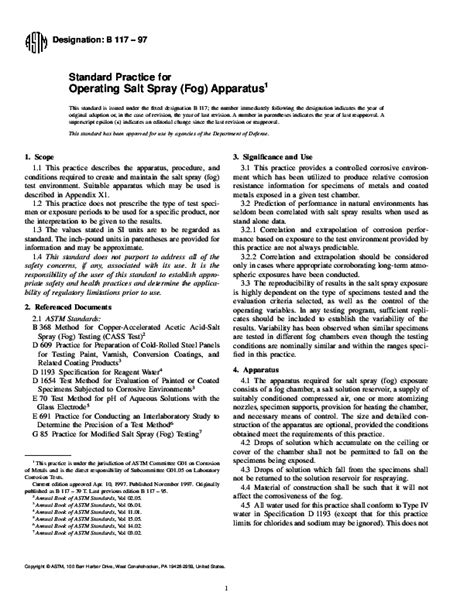

Standard Practice for Operating Salt Spray (Fog) Apparatus B0117-19 ASTM|B0117-19|en-US Standard Practice for Operating Salt Spray (Fog) Apparatus Standard B117 Standard Practice for Operating Salt Spray (Fog) Apparatus> new BOS Vol. 03.02 Committee G01 $ 76.00 In stock The ASTM B117 standard, also known as the “Standard Practice for Operating Salt Spray Fog Apparatus,” is an essential guideline in the field of corrosion testing. This practice defines the standard conditions for operating salt spray fog apparatus to assess the corrosion resistance of various materials. This process helps predict the lifespan of coatings and materials when exposed to salt spray or sea water. Types of Salt Spray Chambers. Traditional Salt Spray Chambers: These are the most common and are used .

The Atlas SF Series are rugged and reliable chambers for traditional Salt fog (spray) and Humidity Testing. SF cabinets are used to quickly qualify a coating or material on a pass-fail basis, or determine the probability of corrosion of a specific material. . ASTM B117, ASTM D1735, ISO9227, GM 4429P, GM 4465P, CASS, SWAAT, Acetic acid, Water .

astm b117 specification

astm b117 salt spray test

The salt fog test ASTM B117, also known as the salt spray fog testing, is a widely recognized standard for evaluating the durability of materials and coatings. . Salt Spray Test Chamber for ASTM B117. Tensile Testing Machine. Single Column Universal Material Testing Machine; Drop Test Machine; Tumble Tester; Q&As on Operation of Salt Fog Test Chambers: The Salt Spray Woes, pH, S.G., Volume of Condensate too low, Concentration too low, etc. . ASTM B117 Salt Fog Test Chamber Operational Q&As, Problems: Salt Spray Woes. Q. With what solution can I unclog the nozzle if it has grains of salt stuck?The Auto Technology Company Standard Salt Fog Cabinet is the basic unit that has served the testing community for over 50 years. Constructed of steel and utilizing a water jacket temperature control system these units are designed to provide the user a robust, simple design to handle the traditional test specifications like ASTM B117 (Salt Fog), Mil-Std-883, Method 1009.5, G85 A1 .

The Role of ASTM B117 The ASTM B117 standard is the most widely used protocol for conducting salt spray tests. Established by ASTM International, this standard provides clear guidelines for setting up and operating a salt spray chamber, ensuring that results are consistent and reliable across different tests and industries. Key Features of ASTM .

ASTM B117 is not a test specification per se, according to ASTM International. Instead, it outlines standard practices for operating salt spray (fog) equipment. ASTM B117 is a document that establishes operating parameters and requirements for salt spray test chambers. It details how to create and maintain a salt spray test environment so that .I-This method is applicable to salt spray (fog) testing of ferrous and non-ferrous metals, and is also used to test inorganic and organic coatings, etc., especially w'here such tests are the basis for material or product specifications. 2. Apparatus 2.1 The apparatus required for salt spray (fog) testing consists of a fog chamber, a salt1 | ASTM B117 How to Run ASTM B117 Standard Practice for Operating Salt Spray (Fog) Apparatus Andy Francis – Marketing Director. Bill Tobin –Senior Technical Marketing Specialist. Dave Duecker – Senior Technical Marketing Specialist. Sean Fowler –Senior Technical Director. Q .

The salt spray test requires specialized equipment, primarily a salt spray test chamber. These chambers provide a controlled and reproducible environment for conducting the test. This section discusses the features of a typical salt spray test chamber, including temperature control, humidity regulation, and mist generation. ASTM E691: Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method G85 Practice for Modified Salt Spray (Fog) Testing; ASTM G85-19: Standard Practice For Modified Salt Spray (Fog) Testing; ASTM B117-19: Standard Practice for Operating Salt Spray (Fog) Apparatus is available on the ANSI store.

tears of the kingdom endurance test

Our durable salt spray testing chambers can test a number of test specimens of many sizes, shapes and dimensions for the ASTM B117 Salt Spray Test. We can also control the duration/timing of the exposure for the test according to specific to customers requirements.

ASTM B117 or salt spray test takes these products/materials and exposes them to controlled conditions to measure these corrosive properties. ASTM D610 is one of the many corrosion specifications used to evaluate samples that have been .Designation: B117 − 19 Standard Practice for Operating Salt Spray (Fog) Apparatus1 This standard is issued under the fixed designation B117; the number immediately following the designation indicates the year of . 7.1 The position of the specimens in the salt spray chamber during the test shall be such that the following conditions are met:ASTM B117 is a document establishing the parameters and requirements for operating a salt spray test chamber. It specifies how to create and maintain the salt fog test environment so that results can be achieved consistently from lab . Explore the functions of a salt spray chamber, highlighting salt spray testing, corrosion test chambers, and relevant standards like ASTM B117, JIS Z 2371, ISO 9227-2017, and ASTM G85. Learn more with Pacorr.. [email protected] .

inside the chamber, and never underneath samples or anything else that could drip into them from above. • Photographs may be taken of the samples at customer specified intervals throughout the test. CorroSalt for Salt Spray Testing (Accessory No: SALA530) Highest purity salt for fully compliant testing. For all salt spray testing including .ASTM B117 Testing – Operating Salt Spray (Fog) Apparatus Study Date: January 2014 Salt Spray chamber used: MI-EQ-477 – Model CTT 1100 – 13-1152-40 Panels used: UNS G10080 steel plates 76 x 127 x 0.8 mm Data source: ASTM B117-11 X3.8 Precision and Bias - Steel Panel Test The ASTM repeatability study gives the acceptable limits (with a 95% .

Learn how to meet salt collection requirements in ASTM B117 and ISO 9227 salt spray tests. Find tips for adjusting fog deposition, measuring pH, concentration, and more. . The test conditions for both are a constant salt fog of 5% sodium chloride concentration at a chamber temperature of 35 °C. To ensure good reproducibility and . The standards ASTM B117, ISO 9227, and JIS Z 2371 play a crucial role in supporting manufacturers in the domain of salt spray testing. Firstly, these standards provide manufacturers with universally accepted guidelines, ensuring consistency and reliability in the evaluation of corrosion resistance for metallic materials.SS and SSe Series Salt Neutral Spray Corrosion Chambers (Salt Fog), also known as the Salt Mist Chamber, were built to meet the requirements of ASTM B117, ISO 9227 Neutral, CASS, AASS – JIS Z 2374 Neutral, CASS, AASS and DIN 50021.. The following are construction characteristics of the equipment that are very important to ensure the repeatability and .

By subjecting test specimens to the ASTM B117 Salt Spray Test, engineers can assess the performance of coatings and materials, enabling them to make informed decisions during the design and production processes. Salt mist test chambers also play a crucial role in the aerospace sector.

Applied Technical Services offers ASTM B117 testing services that determine the corrosion resistance qualities of metals and coated metals. Our accredited salt spray testing lab conducts accelerated corrosion testing that simulates real-world .

Here conventional salt spray is often combined with one other climate, in a two-part cycle, to accelerate the test. For example: salt spray and condensation humidity (SWAAT) or salt spray and drying (PROHESION) or salt spray and SO2 testing. (ASTM G85 A4) Seven model sizes: Salt Spray Chamber Size Range. 120 Ltr (4.2 cu ft) 300 Ltr (10.5 cu ft)Let us go a little more into detail on three of the main standards our Salt Spray Chamber meets : ASTM B117: This is the most common standard which has widely been accepted in the concerns of salt spray testing. It basically offers operating conditions for a salt fog apparatus, such as conditions to be maintained by temperature, humidity, and .

astm b117 salt spray specification

Bem-vindo ao casino online da Solverde.pt, o site onde podes encontrar os melhores jogos de casino, as apostas desportivas mais variadas e as promoções mais vantajosas. .

astm b117 salt spray chamber|astm b117 rating scale